:15642202798

1. Purpose

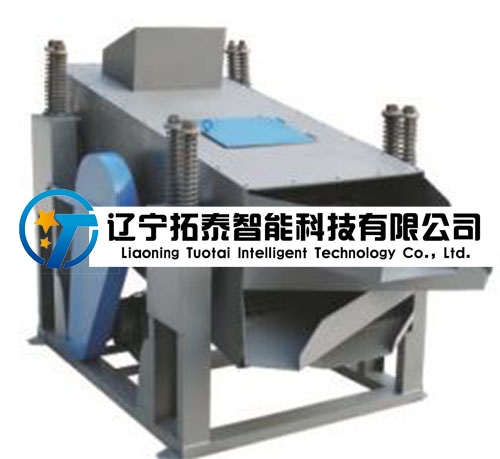

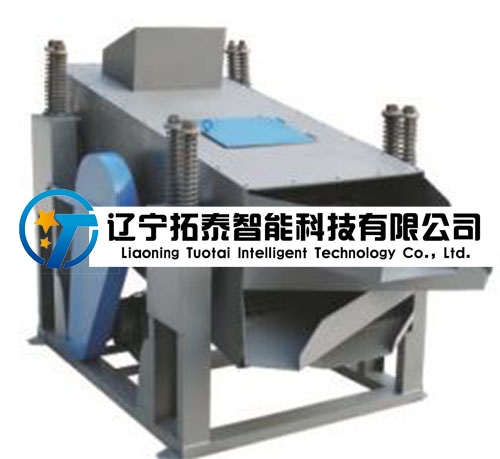

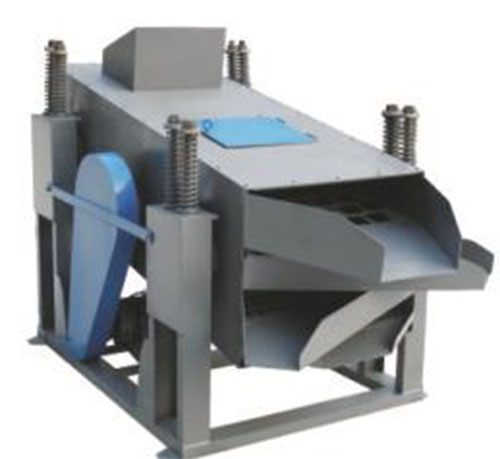

TT-ZSQ-02 grouped mechanical sieve in front of coke drum is mainly used for the determination of various levels of metallurgical coal coking composition (25-40mm, 40-60mm, 60-80mm, >80mm) coke dust content. It can replace manual sieve, improve the detection accuracy of coke powder content, is an ideal equipment to eliminate human error. The mechanical screen adopts optimized design to make it compact in structure easy to operate. Its technical performance has reached the requirements in GB/T2005-1994. Coke thermal strength

2. Technical parameters

Sieve plate specifications (mm): 80*80 60*60 40*40 25*25

Number of floors: 4 floors

Screen body inclination: 11.5℃

Excitation amplitude: 3-6mm

Effective area of sieve: 1630mm*700mm

Motor power: 2.2kw

Dimensions (mm): 2100*1340*1310

Three, structure overview

The machine is composed of a frame, a power part, a deceleration part, a shock absorption part, a screening part. The frame is welded by a variety of high-quality steel materials, which mainly supports various components. When the power is turned on, the motor rotates drives the flywheel with the weighted machine to rotate through the V-belt. Due to the weighted mechanism, the screen body works with the designed amplitude exciting force, the material completes the grouping screening process under the vibration. According to the needs of work, the machine can work continuously.

In order to stabilize the machine, increase the excitation force, reduce the damage caused to the machine by the excitation force, control the noise, the machine is designed with a shock absorption mechanism.

The screening part is designed as a four-layer five-level sieve plate, all the sieve plates are square holes, the sieve body is welded by high-quality steel plates.

Fourth, installation commissioning

The equipment can be installed on a concrete foundation placed on a flat ground. At the same time, measures must be taken to prevent the displacement of the machine caused by the vibration produced by the machine. it must have rain shelter, install use it as far as possible without leaking the sky. Convenient maintenance should be considered for indoor installation.

After the equipment has been installed, if it is installed on a concrete foundation, it must exceed the concrete solidification period before it can be commissioned. Before the test run, check whether all the bolts are tightened again. When all the connections are confirmed that there is no obstruction to the movement, you can start the power-on test run. The test run with an empty machine for more than 30 minutes. Observe that the machine has no impact, no noise, no loose parts, temperature rise of each bearing If the temperature is lower than 65°C, if the above faults are found, immediately shut down for maintenance. After confirming normal operation, load operation can be performed. After three cycles of trial operation, it can be used for normal production.

Five, matters needing attention

Operation sequence:

When in use, the mechanical sieve should be started first, when the normal amplitude is reached, the sample is added to the rear end of the upper layer of the mechanical sieve. The machine can feed continuously work continuously.

Each layer of material is collected its own material port. When the sieving effect is affected by the scorch of the screen hole, it can be removed the side door of the screen body.

After screening, the feeding should be stopped first then the machine should be shut down, then the materials should be classified weighed.

This machine is a strong vibration machine. Every shift must check whether the connecting parts of each part are loose, whether the shock absorber spring is broken, whether the screen plate is loose. If an abnormality is found, remove it immediately.

The electrical part should have a reliable grounding device.

Measure the size of the sieve once a month, replace it immediately if it exceeds the regulations.

Contact: Manager Zhao Loaded Coke

Oven Loaded Coke Oven Loaded Coke

Oven Loaded Coke Oven Loaded Coke

Oven Loaded Coke Oven

Hand machine: 15642202798

Coke thermal strength Coke

thermal strength Coke thermal strength

Fax: 0412-5291088