:15642202798

PETRO 100AI intelligent coal rock testing system (manual revision level)

1 Introduction

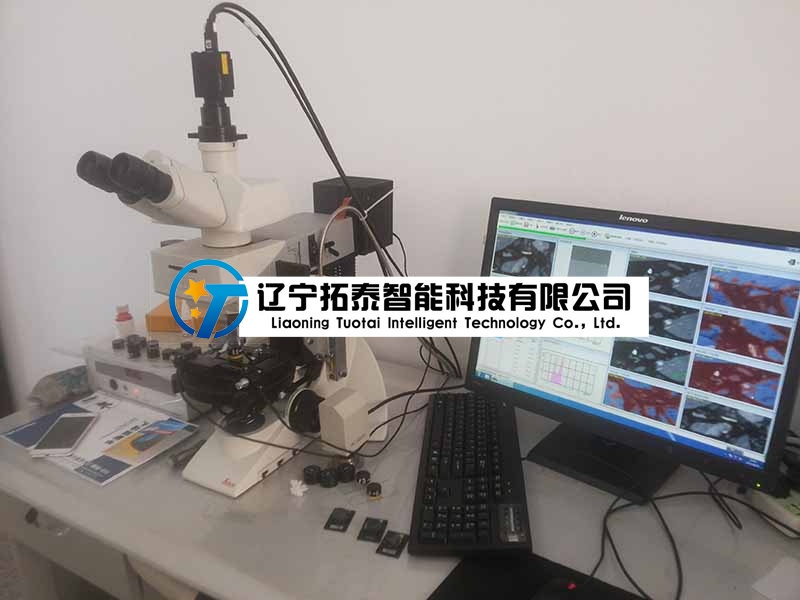

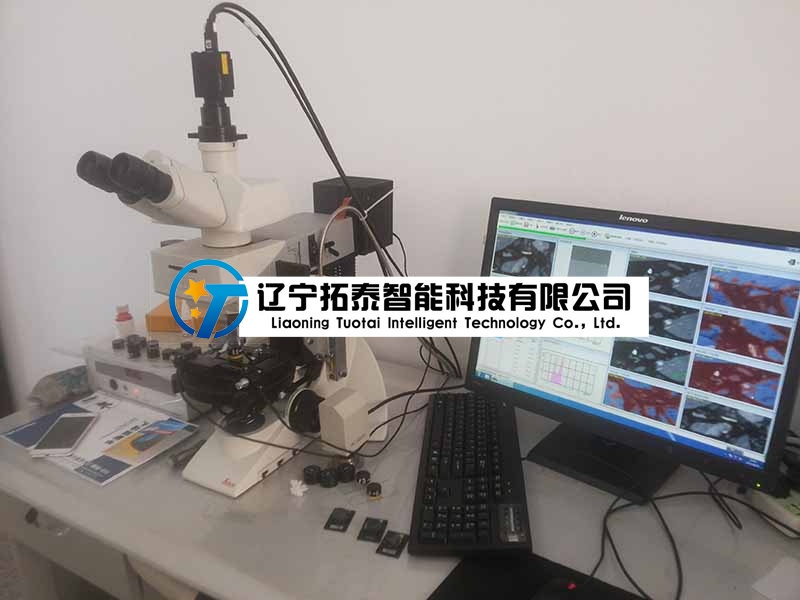

PETRO 100AI intelligent coal rock testing system (manual revision level) is a new type of coal rock automatic testing system based on image analysis developed by our company. The system is mainly composed of a reflection polarizing microscope, a microscope camera, an automatic stage, an image acquisition control system, an automatic coal rock test system.

2 System function

This coal rock automatic testing system has 8 core functional modules. The details are as follows:

1) Image acquisition: Use the image acquisition control system to control the automatic stage, automatic focusing device microscope camera to realize automatic image scanning acquisition.

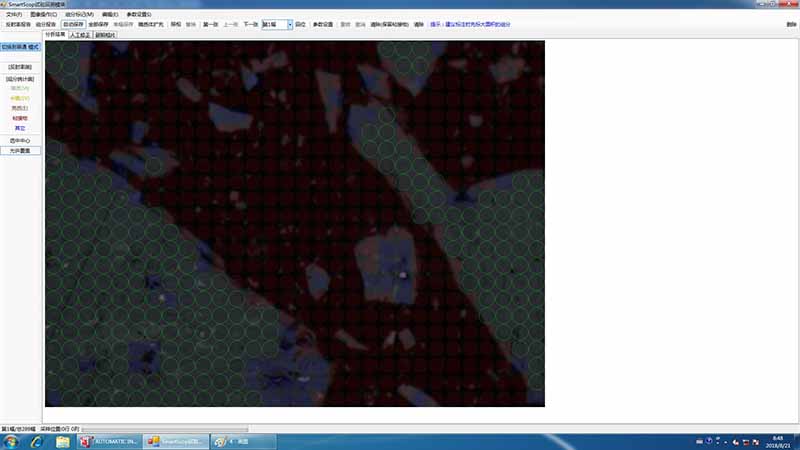

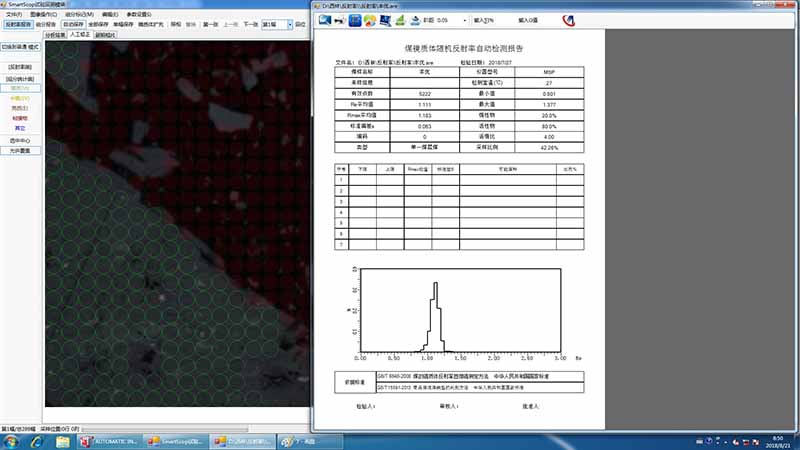

2) Automatic test of reflectivity: Based on image analysis, it can automatically identify vitrinite test its reflectivity, without manual intervention, automatically generate reflectivity test report, the process is traceable auditable. Vitrinite recognition results reflectance measurement values are marked on the image, which is convenient for reviewers to review the test process results during after the event, also for quality management personnel to analyze judge the composition properties of coal.

3) Review of reflectance test results: A separate review can be conducted specifically for whether a specific coal type is mixed to improve review efficiency efficiently resolve coal type disputes; for mixed unconventional coking coals, such as lignite, long flame coal, anthracite Can be accurately quickly reviewed confirmed.

4) Traditional method of reflectivity test: refer to GB/T 6948, based on image analysis, perform vitrinite reflectance test the center of the field of view. The vitrinite reflectance test results coal discrimination results of each image can be marked in The image above ensures that the test process is traceable auditable, facilitates communication, intuitively resolves coal disputes.

5) Mixed coal stripping coal classification: According to the characteristics of the reflectance distribution map, the stripping of the mixed coal reflectance distribution map is carried out. It provides three types of coal discrimination modes: simple discrimination method, interactive discrimination method, origin discrimination method.

6) Coal blending fitting: use the reflectance test results of a single coal the preset coal blending ratio to fit the reflectance histogram average value of the coal blending to guide coking coal blending. This module also includes the calculation of the composition equilibrium constant CBI the intensity index SI, which can be used to specify the conversation quality prediction model.

7) Quantitative composition statistics: Based on image analysis, the composition (microscopic composition content, microscopic coal type) quantitative active inertia ratio determination, the process is traceable auditable. Microscopic component quantification provides two methods: "online" testing "offline" testing.

8) Multiple levels of image processing programs can be authorized for testing, reviewing, evaluating coal quality, communicating with users, etc. for testing operators, reviewers, coal quality managers marketing personnel, all levels are adjustable The test results corresponding images are provided to facilitate application communication.

3 System technical parameters

(1) Main functions technical parameters of the image acquisition system

1) Image acquisition speed quality: Perform coal rock analysis with reasonable sample moving speed necessary residence time. On this basis, the time for acquiring about 900 images is controlled within 23 minutes, the image acquisition clarity rate reaches more than 95%.

2) The automatic acquisition process adopts the automatic focusing method according to the image definition, the focusing method does need manual assistance.

3) The image sensor of the camera is a Charge Coupled Array Detector (CCD) with a bit depth of 16 bits a chip size of 2/3 inch.

4) The overall dimension of the automatic stage is W310*D215*H63 (mm). X, Y stroke is 50mm, X, Y minimum step accuracy is 0.05μm, repeat positioning accuracy is less than 1μm.

5) Z-axis motorized focusing, the accuracy is 0.02μm (related to the design parameters of the microscope focusing mechanism), the step angle of the stepping motor is 1.8º.

6) The automatic stage can be controlled by software manually.

(2) Image analysis testing technical parameters

1) The method of establishing the working line of vitrinite reflectance is the method of establishing the working line in real time, the method of correcting the instrument parameters with a fixed working line cannot be used.

2) Image processing speed: automatic identification of vitrinite group automatic measurement of reflectance of 900 images can be completed within 5 minutes.

3) Component content test: According to the microscopic component image, determine the microscopic component content active inert ratio.

4) The test process test result data are automatically saved. The testing data testing process must be traceable. The vitrinite reflectance test results coal discrimination results of the center image of each field of view can be marked on the image.

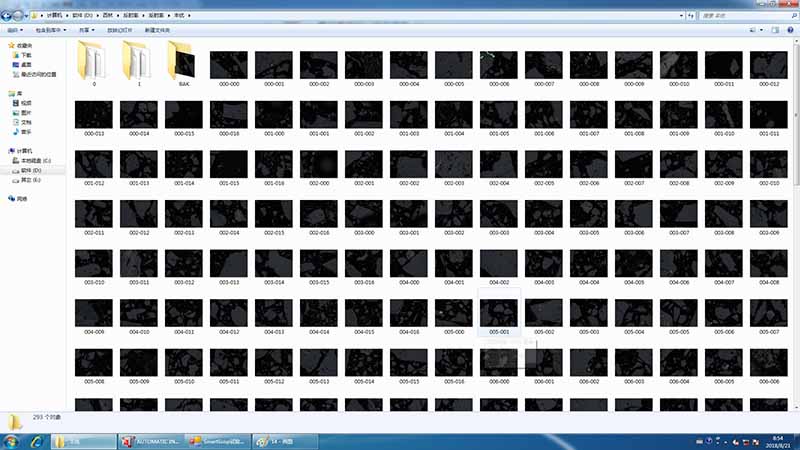

4 The whole process of the system is traceable the interface of manual retouching

The software can realize two functions of current experiment tracing historical experiment tracing:

among them:

The current experimental method can control the electric moving stage to move the sample back to any position for re-sampling testing.

Historical experiment method, in order to retrieve the experiment done before, you can view the whole process, correct the identification error reissue the correct version of the report.

The approximate process is as follows:

This is the original 16-bit high-precision reflectance value data file package of all pictures saved in the overall automatic scanning process each coordinate point in each picture (folders 0 1)

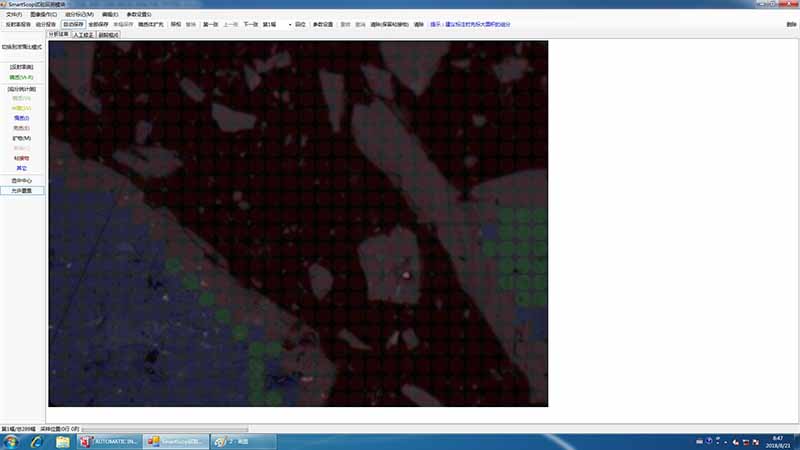

The interface after opening one of the experimental results:

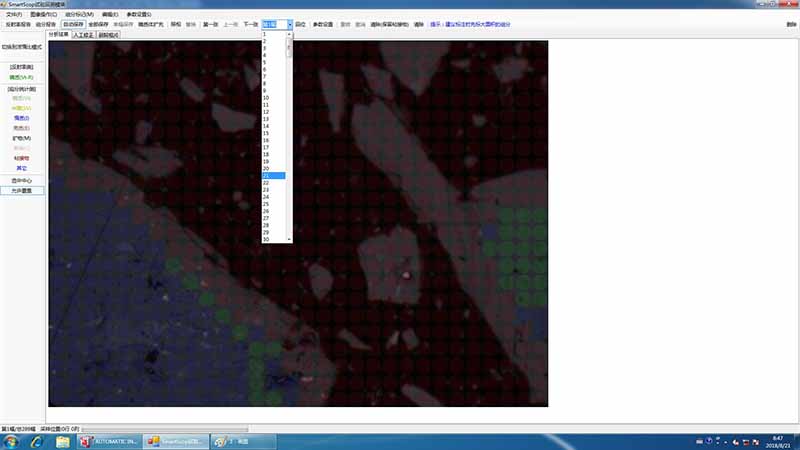

You can choose any picture to be corrected

If there is an error, click "Clear" first, then click again to the correct result.

After all corrections are completed, you can click "Reflectivity Report" "Coal Composition Report", the software will automatically regenerate the correct report based on the corrected results.

Contact: Manager Zhao Loaded Coke

Oven Loaded Coke Oven Loaded Coke

Oven Loaded Coke Oven Loaded Coke

Oven Loaded Coke Oven

Hand machine: 15642202798

Coke thermal strength Coke

thermal strength Coke thermal strength

Fax: 0412-5291088